About Julun

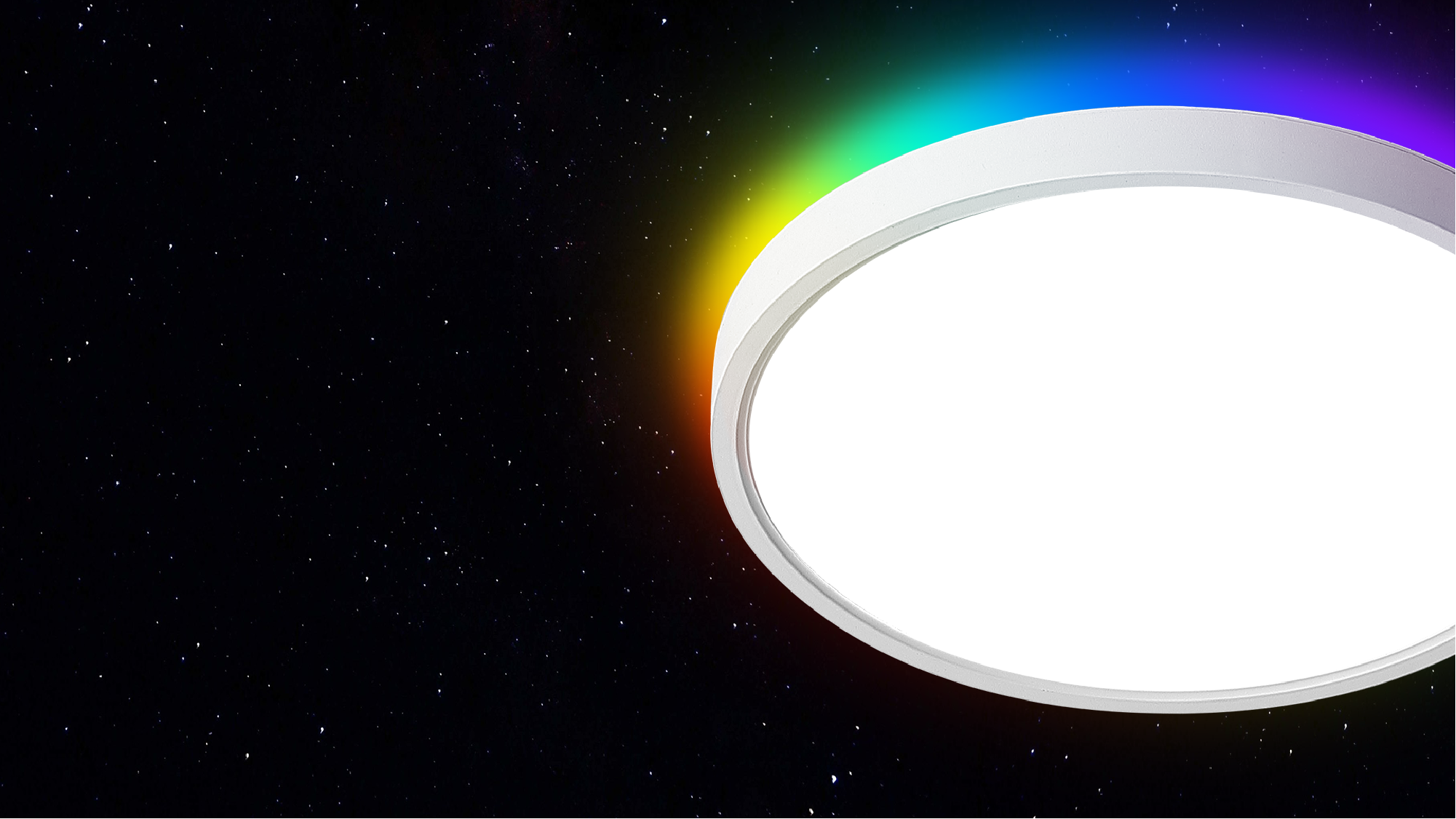

Smarter Lighting, Life Made Extraordinary

From a five-person startup to a 6,000 m² smart-lighting manufacturer, engineering light that goes beyond the ordinary.

Company at a Glance

-

Founded 2017

Innovating since day one

-

100+ People

Production & operations professionals

-

6,000 m² Facility

Modern manufacturing floor

-

> RMB 50M Output

Annual output value

-

CE • RoHS • FCC

Model-specific certifications available

Our Story

Founded by visionary young talents Max and Given in 2017, Julun Lighting has grown from a five-person elite team into a comprehensive enterprise integrating in-house R&D and high-efficiency manufacturing. Today, we operate a 6,000 m² modern facility with 100+ professionals, delivering smart downlights, floodlights, pendants, and fan lights trusted by global partners.

We build quality into every step. Our production lines combine high-precision SMT and DIP, machine-vision placement & defect inspection, smart material management, online testing, and full aging tests before shipment—assuring stability, safety, and long-term reliability.

With Tuya-enabled connectivity and seamless compatibility with Alexa and Google Assistant, our products bring effortless voice control, scene modes, and energy-saving intelligence to everyday life.

Milestones

2017 — Founded by Max & Given; 5-person core team.

- Julun Lighting was established by Max and Given with a clear mission: blend in-house R&D with efficient manufacturing.

- Set our brand pillars: innovation, reliability, and customer-first service.

- Built the first pilot line and quality workflow for small-batch production.

2018 — SMT + DIP lines commissioned; OEM/ODM launched.

- High-precision SMT and reliable DIP lines came online to secure placement accuracy and robust soldering.

- Introduced OEM/ODM services with strict process control from materials to final inspection.

- Standardized functional tests and burn-in to ensure stability before shipment.

2019 — First smart downlight series released.

- Debuted our first smart downlight family with app control, dimming, and scene presets.

- Established a modular design approach that later enabled fast iterations across product types.

- Opened new channels in project, retail, and e-commerce markets.

2020 — Tuya integration; app & cloud connectivity.

- Partnered with Tuya to adopt dual-module chips for stable connectivity and lower power consumption.

- Achieved seamless control via mobile app, Amazon Alexa, and Google Assistant.

- Enabled cross-device interoperability for homes and small commercial spaces.

2021 — Core lines certified CE/RoHS/FCC.

- Obtained CE, RoHS, and FCC compliance for major product lines.

- Implemented documentation, traceability, and sampling plans aligned with export requirements.

- Expanded reliability tests (thermal, surge, hi-pot, and aging) to strengthen quality assurance.

2023 — Facility expanded to 6,000 m²; 100+ staff.

- Upgraded to a 6,000 m² modern workshop with 100+ production & management professionals.

- Introduced machine-vision QA and intelligent material management to boost throughput and reduce errors.

- Rolled out in-line QC gates and continuous process optimization across stations.

2024 — Annual output surpassed RMB 50M.

- Crossed RMB 50M in annual output—an important validation of capacity and market recognition.

- Matured our OEM/ODM execution with faster lead times and consistent quality at scale.

- Broadened the smart lineup (downlights, floodlights, pendants, fan lights).

2025 — Driving greener, smarter lighting worldwide.

- Focus on higher-efficacy designs and energy optimization across the portfolio.

- Expand integrations with mainstream smart-home platforms for smoother, safer user experiences.

- Advance sustainable practices—from materials and packaging to manufacturing footprints.

Factory Tour

Partner with Julun

OEM/ODM projects worldwide. Tell us your application, target certifications, and timeline—we’ll reply within 1 business day.